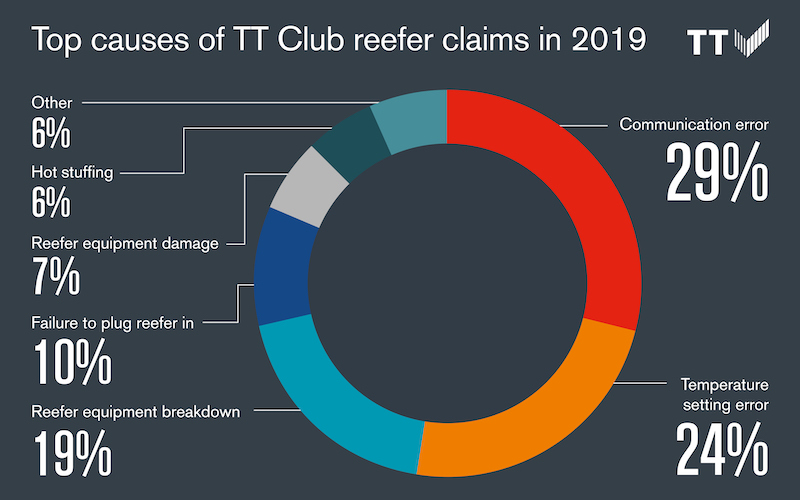

ANALYSIS of specialist insurer TT Club’s claims records for transport operators over the past three years shows temperature-controlled incidents ranking in third place. Almost 30% of these incidents involved a miscommunication of operational instructions on care of the cargo with a further 23% down to temperature setting errors. Reefer equipment failure or damage accounted for a quarter of the claims.

TT continues in its attempts to minimise losses for both its members and all those involved in the cool supply chain with publicly available guidance documents and increasingly via online webinars. The latest was held last week, with causational information as well as advice on risk avoidance. A recording is available here.

“Our own experiences and the data drawn from our claims history was reinforced by over a third of webinar attendees, who when asked their perception of the primary risk factors, pointed to communications errors with ambiguous or incorrect instructions passed between supply chain stakeholders,” said Mike Yarwood, TT’s loss prevention managing director.

The sensitivity of many commodities transported under temperature-controlled conditions puts the care of the product both before and during transit as a paramount concern.

During TT’s webinar, Carsten Jensen, a consultant and surveyor specialising in perishable goods transport gave a comprehensive insight into the five key aspects that impinge on loss prevention: product quality; preparation of the goods; correct packaging and stowing; attention to temperature irregularities and prolonged storage and transit.

“Clearly a number of these processes are outwith the control of forwarder, carrier and terminal operator,” Mr Yarwood said.

“But as the demand for unitised transport of perishables continues its upward trend, it is vital that the transport links in the chain become more informed about all the relevant processes to improve the collaborative efforts of all stakeholders.”