TOGETHER with Richard Wilding, professor of supply chain strategy at Cranfield University in the United Kingdom, DHL has released a white paper envisioning possible changes in supply chains following the current pandemic.

By analysing the impact of COVID-19 on key supply chain drivers, the paper provides several strategies and actions to set up supply chains of the future. Based on real cases, the paper outlines possible scenarios for how the logistics industry could transition to a new normal from the current pandemic status quo.

“With the easing of restrictions and the unfreezing of the economy in many regions of the world, it is time to establish a first retrospective summary on the resilience of global supply chains,” says Katja Busch, chief commercial officer, DHL, and head of DHL customer solutions and innovation.

“For us as logistics experts, it is important to analyse the challenges and experiences across industries during this crisis and to envision how resilient supply chains can be in the future so that we may best advise our customers.

“As a world leader in logistics, we have the insights and the expertise to accurately evaluate the situation.”

The white paper suggests the various implications for businesses, supply chains, and supply chain leaders can be subsumed under four categories: resilience issues, demand-related issues, transportation and warehousing-related issues and workplace-related issues.

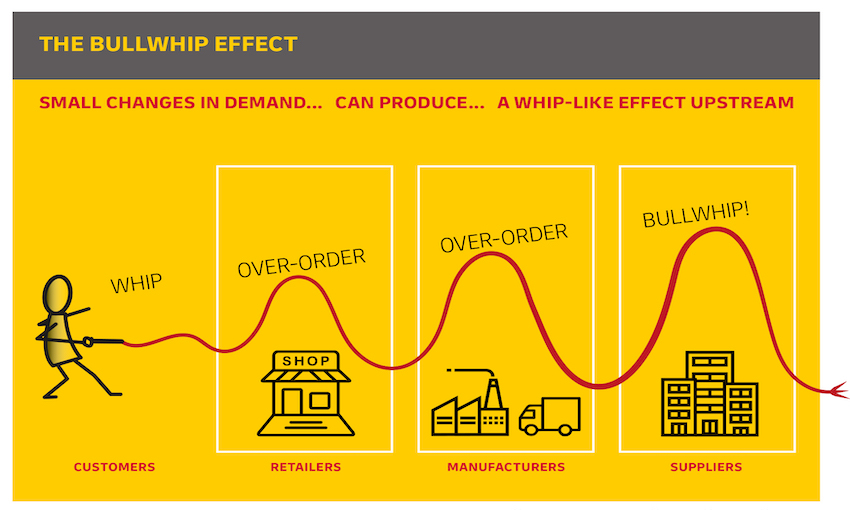

“The photographs and TV images were stark. Long before countries went into lockdown, their supermarket shelves were stripped bare. Factories and distribution have a delayed reaction to extreme fluctuations in demand,” Professor Wilding said.

“In the end, fear of lock-down-induced supply chain disruption was no longer the trigger. People were panic buying because other people were panic buying.

“In the new normal, if your supply chain is the same as the one that you had pre-coronavirus, you’re probably doing something wrong.”

In a pre-new normal world, supply chains will be re-shaped to make them more resilient, says the white paper. For instance, the fact that both manufacturing and warehouse locations were equally affected by regional lock-downs and varying regulations, will result in more distributed manufacturing, storage, dual sourcing, re-shoring, and near-shoring in the future.

Furthermore, demand will be more volatile and consumer tastes may erratically fluctuate, increasing the need for flexible and alternative transportation flows and warehouse networks.

The paper suggests that while online shopping will be more prevalent and direct-to-consumer sales will increase, other retail channels and industries will be disrupted. These are just some of the facets that influence modern supply chains.