RIO Tinto Shipping is trialling further technology designed to improve efficiency and reduce emissions, by retrofitting a drag-reducing air lubrication system to one of its bulkers.

The company has chosen Alfa Laval’s OceanGlide fluidic air lubrication, claimed to be an innovative system aimed at enhancing a ship’s propulsion efficiency and energy savings while sailing.

AlfaLaval says OceanGlide, introduced in 2023, has generated considerable interest from shipowners seeking to address energy efficiency and emission challenges. The Swedish company says it is is proven to reduce specific drag from 50–75%, which means significant propulsion power savings, leading to lower fuel consumption and reduced CO2 emissions. The combination of these benefits positions it as a future-proof solution for improving vessel performance, it says.

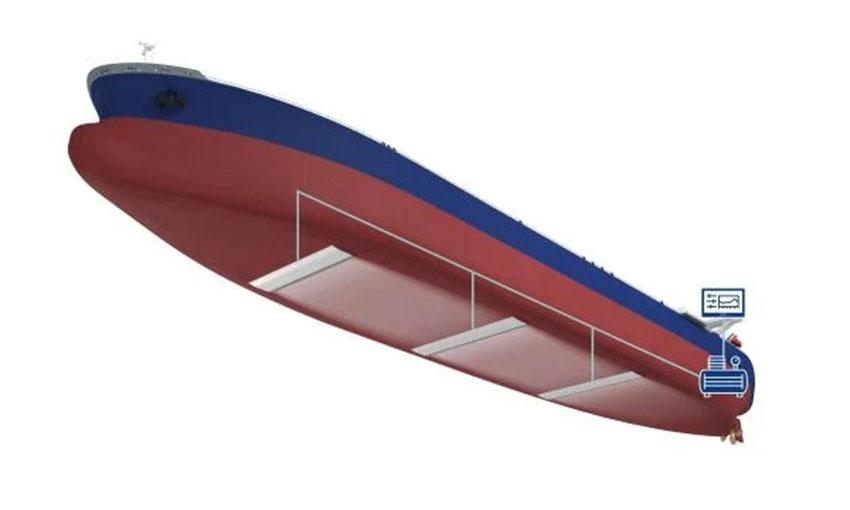

The solution combines air lubrication with fluidic technology to create an even air layer with high efficiency and little compressor power. Through this approach, OceanGlide creates a more streamlined air layer on the vessel’s flat bottom by dividing the surface into segments, with each segment featuring its own fluidic band. The independent steering of each band allows a more controlled airflow to reduce friction between the hull and water. This distribution of bands into sections creates a more dynamic air layer, maximizing coverage and eliminating passive cavities along the vessel’s underside.

The system requires no structural modifications, AlfaLaval says, except for three to five hull penetrations of a maximum DN150. This ensures easy adaptation to existing classification certificates without necessitating any major changes or conversions, making it ideal for retrofitting as well as for newbuilds. The fluidic bands, designed with a low profile and no moving parts, can be configured underneath the ship at any shipyard with ease.

“We are delighted about OceanGlide being selected as one of the promising technologies that can support Rio Tinto in its decarbonisation journey,” Rajiv Sarin, Head of Air Lubrication, Alfa Laval, said.