THE latest data from cloud-based platform project44 shows that carriers, throughout December 2021, increased blank sailings and other schedule adjustments resulting in more empty shelves and potentially more disappointed consumers.

The global phenomenon of port congestion and ship delays impacted all major ports in Asia, Europe, the Middle East and the United States.

project44 reports there is no immediate relief in sight, with the short-term outlook for 2022 is expected to be a continuation of 2021.

China’s zero-COVID policy is playing a major role in shipping delays.

Josh Brazil, VP of supply chain data insights at project44 said, “COVID impacts to shipping will be a toss-up in terms of labour available at Asian manufacturers, ports and throughout the supply chain.

“This will likely continue to impact carriers’ schedule reliability which in turn will cause a ripple effect downstream of supply chains.”

He said spot rates will remain high throughout most of 2022 however it’s unlikely port conditions will return to pre-pandemic levels.

While carriers have implemented various strategies, including blank sailings and sailing schedule changes to improve on-time reliability it has not proven as successful as carriers had hoped.

These measures resulted in shippers paying higher freight rates and experiencing delivery delays.

According to Nicholas Sly, an economist with the Kansas City Federal Reserve Bank, a 15% increase in shipping costs leads to a 0.10 percentage point increase in core inflation after one year.

Carriers like Maersk expect the exceptional market conditions in shipping to persist until the first quarter of 2022 or longer.

Meanwhile, economists at Goldman Sachs expect backlogs and elevated shipping costs to persist at least through the middle of 2022. A reason for that is that there is no immediate and short-term solution for the underlying supply-demand imbalance at US ports.

“Blank sailings will continue well into 2022 as ports work down backlogs and consumer spending remains strong,” Mr Brazil said.

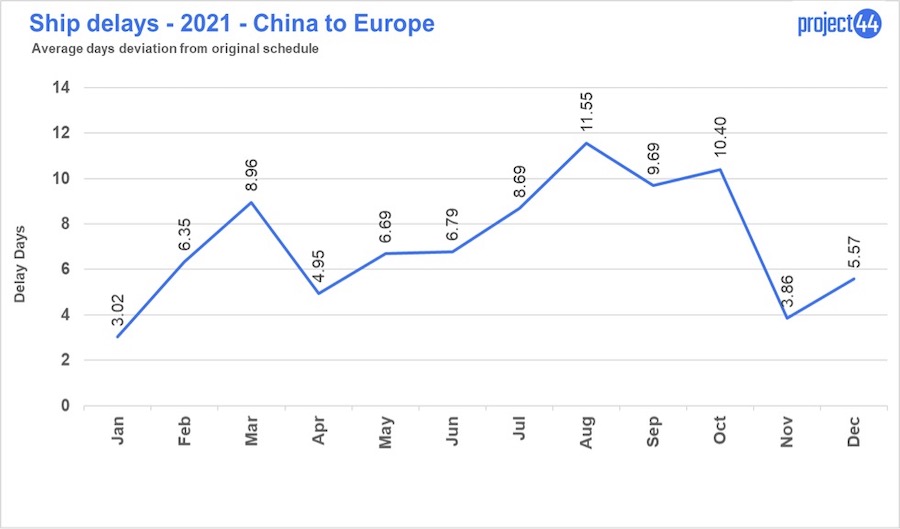

Ship delays

The number of ship delay days to the US west coast has been steadily increasing since October. This coincides with the holiday peak season in the US. Typically the peak occurs in September but 2021 was not a normal year for the ocean freight market as retailer inventories ear-marked for the holiday season arrived at stores later in the season due to port congestion on the US west coast.

Fingers pointed to the lack of truck drivers to move stacks of containers from ports quickly in order to make room for incoming containers, according to project44.

On the east coast, the opposite occurred. Since October, the number of ship delay days has declined. The decline was likely due to various measures ports such as Savannah took to ensure carriers could load and unload containers in a timely manner.

Blank sailings

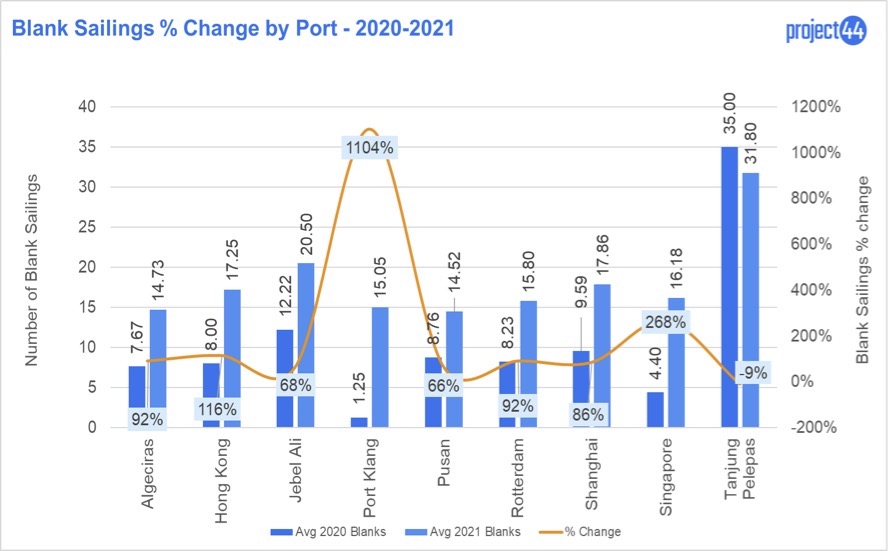

A shift from Ningbo port to Shanghai because of COVID outbreaks backfired on some shippers as congestion at Shanghai increased. As a result, Shanghai recorded an 86% increase, year-over-year in blank sailings.

Meanwhile, Klang experienced heavy rainfall and flash floods which affected port operations. According to authorities, warehouses, container depots and roads were flooded. Because of the weather conditions, carriers bypassed the port.

Other ports experiencing year-on-year increases in blank sailings included Rotterdam, Singapore and Hong Kong primarily due to global port congestion which resulted in ships not getting back to these ports in time.

Transit times and schedule changes

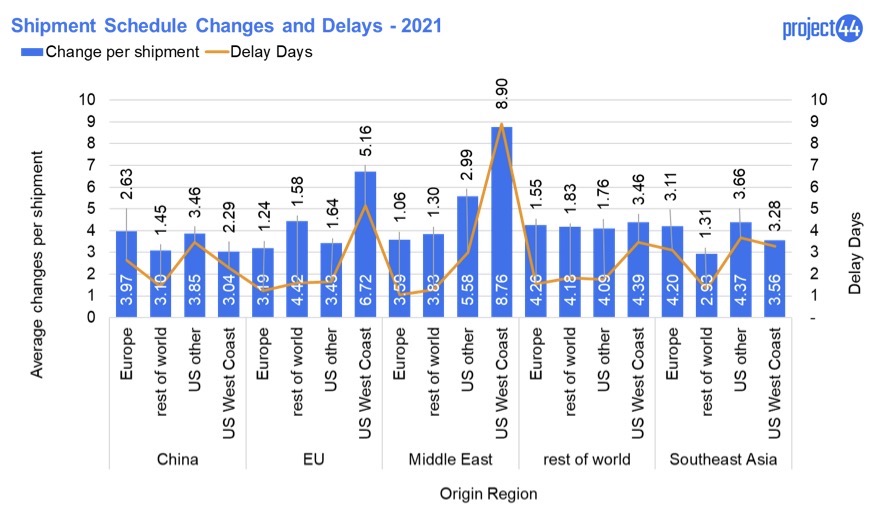

Transit times increased from China’s leading ports to Los Angeles/Long Beach due to port congestion due to which ships were either slow steaming or loitering off the coast of Mexico and other locations before arriving in US west coast waters. The new queuing system at west coast ports also seems to have played a role in this increased transit times although it has reportedly helped with the air pollution situation in that area.

Shipments from the Middle East to US west coast had the most schedule changes resulting in most number of delayed days followed by shipments from EU to US west coast and other combinations were also affected.

Freight rates versus performance

After little change from October to November, Shanghai to Long Beach median delay days and average spot rates increased from November to December. Over 100 ships lined up to enter Long Beach and Los Angeles during December while the threat of a container dwell fee helped move full containers from the complex during the month.

Meanwhile, despite rising spot rates from Shanghai to New York, median delay days continued to improve, a trend that began in September. But some issues such as the omicron variant, the year-end holidays and an increase in charter vessels that need one-time berth space resulted in delays during December.